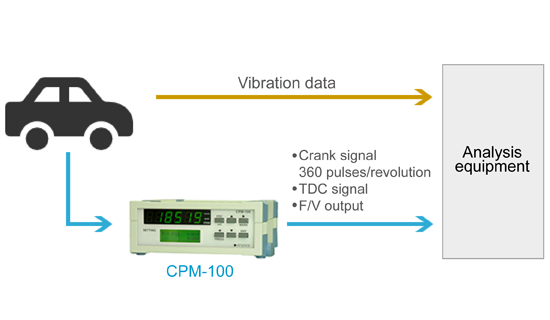

Without mounting a rotary encoder on the engine crank section, the real-time generation of a 360 pulse/revolution crank angle signal by the multiplication of the position sensor output from the plate and crank vehicle parts.

This output timing can be utilized as the measurement trigger signal for vibration analysis equipment. And the high-speed F/V output is very convenient as it is fitted as standard.