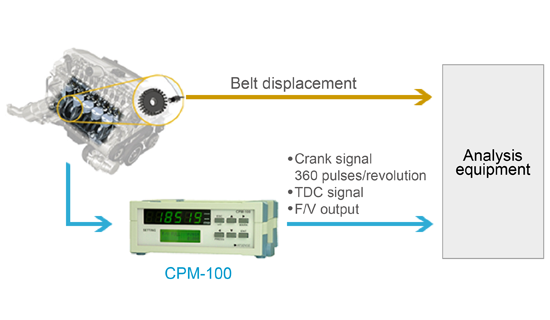

Without the mounting of a rotary encoder for the engine, a crank angle signal of 360 pulses/revolution can be generated in real-time by multiplying the output from the position sensor on the plate/crank vehicle parts.

The amount of belt displacement can be measured using this output timing as a measurement trigger signal.